Paper trays produced by paper tray making machine are used for holding and protecting delicate items like eggs and fruit. Made out of recycled paper, these trays are not only effective at preventing bruising, breakage, and other problems but they are also environmentally friendly. And you can produce other trays by this egg tray machine.

How Paper Tray Making Machine Works?

Below is an overview of how paper tray making machines work. This should give you a better understanding of how these trays are made. The process is rather simple. And you will interested in pulp molding machine price.

Step #1 – Loading Paper Into The Machine

With this step, discarded paper products like newspapers and sales flyers are loaded into the machine via a conveyor belt. The conveyor belt carries the paper to a special blending chamber.

Step #2 – Creating Paper Pulp

Once the paper is in the machine, it is mixed with water and stirred around to create paper pulp. The grayish color of the resulting pulp is created by the different colors of paper mixing together with one another.

Step #3 – Filtering The Pulp

After the pulp is created, it is filtered to remove any contaminants or impurities. This helps ensure that any items that were in the mix are removed before the paper trays are made. Once this process is over, the pulp is delivered to a special holding tank.

Step #4 – Forming The Pulp Into Trays

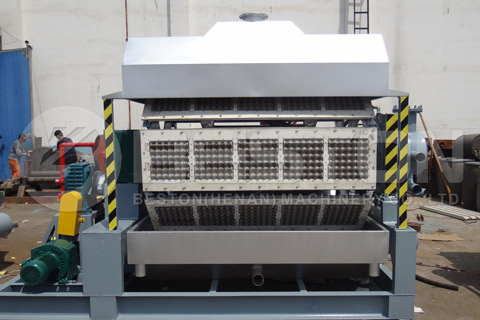

Special molds are used to form the paper pulp into trays. Most paper tray making machines have interchangeable molds, meaning that they can be used to make a variety of different styles of trays. The pulp in the holding tank is sprayed onto the molds until it reaches a certain thickness. The trays are then removed from the molds and placed onto a large conveyor belt.

Step #5 – Drying The Trays

During the next part of the process, the trays move through a special portion of the machine that is designed to dry them out. During this process, the excess moisture is removed from the trays, leaving them dry and ready to use.

Step #6 – Removing The Trays From The Machine

The final part of the process involves removing the finished trays from the machine. Most of the time, this portion of the process is handled by humans. Once the trays are removed and stacked together, they can then be bundled up for shipping.

First, recycled paper is converted into pulp. Any impurities are removed from the pulp and it is sent to a holding tank. A special nozzle sprays the pulp onto molds, continuing to spray until the trays are as thick as they need to be, depending on the application.

After the trays are removed from the molds, they are then thoroughly dried to remove all traces of moisture. During the final part of the process, human workers remove the trays from the machine, stack them, and prepare them for shipping. Visit BestonMachinery.com for searching different models.

These machines provide an environmentally-friendly way to reuse discarded paper products that would have otherwise found their way into the trash.