Paper trays are commonly used in a variety of settings, including businesses, schools, and homes. These trays can be used for a variety of purposes, such as holding documents, files, or other materials. A paper tray making machine is a type of machinery that is used to create such paper trays. There are a variety of different types of the paper tray making machines available on the market, each of which has its own set of features and benefits. When choosing a paper tray making machine, it is important to select one that is best suited for the specific needs and requirements of the business or individual.

Technology behind paper tray making machine

Paper tray making machines are one of the most versatile machines on the market. They are able to produce a wide variety of shapes and sizes, making them ideal for a variety of applications. The egg tray manufacturing machines use a variety of different technologies to produce their trays. One of the most common methods is die cutting. This process involves using a sharp knife to cut the paper into the desired shape.

Another popular method is thermoforming. This process uses heat and pressure to mold the paper into the desired shape. Once the trays have been created, they can be used for a variety of purposes. One popular use is as food trays. These trays can be used to serve food in a cafeteria or buffet line. They can also be used to package food products for sale in a grocery store. Many people also use paper trays as storage containers. These trays can be used to store a variety of different items, such as office supplies or hardware components. They can also be used to organize and store paperwork. Paper tray making machines are an essential piece of equipment for any business that produces paper products. These machines offer an affordable solution for creating a variety of paper products: https://pulpmouldingmachines.com/egg-tray-making-machine/manufacturers/.

How does the machine work?

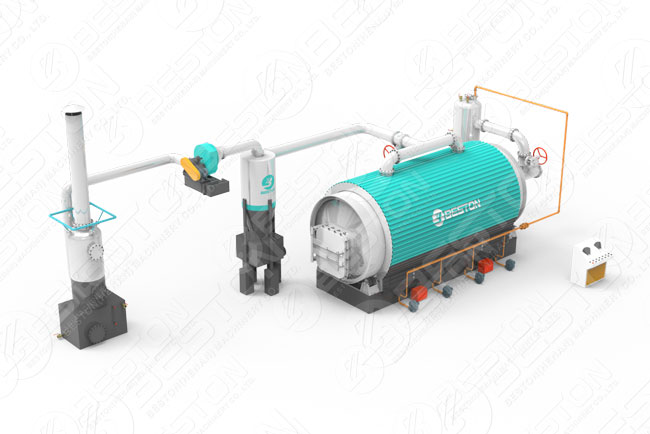

A paper tray making helps in the mass production of paper trays. The machine is operated by a worker who feeds sheets of paper into the machine. The machine then uses a variety of tools to cut, score, and fold the paper into the desired shape of the tray. Once the tray is complete, it is ejected from the pulp molding equipment and can then be used to hold various objects.

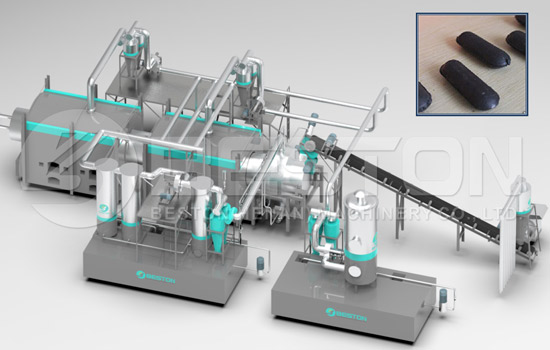

It is a versatile tool that can be used to create a variety of different tray designs. With the help of this machine, businesses are able to save time and money by mass-producing paper trays instead of having to create them by hand. In addition, the small egg tray machine ensures that all of the trays are identical in size and shape, which helps to improve the overall appearance of the products that are displayed in them.

As you can see, there are many benefits to using a paper tray making machine in your business. Not only will it help you save time and money, but it will also help you produce a higher-quality product.