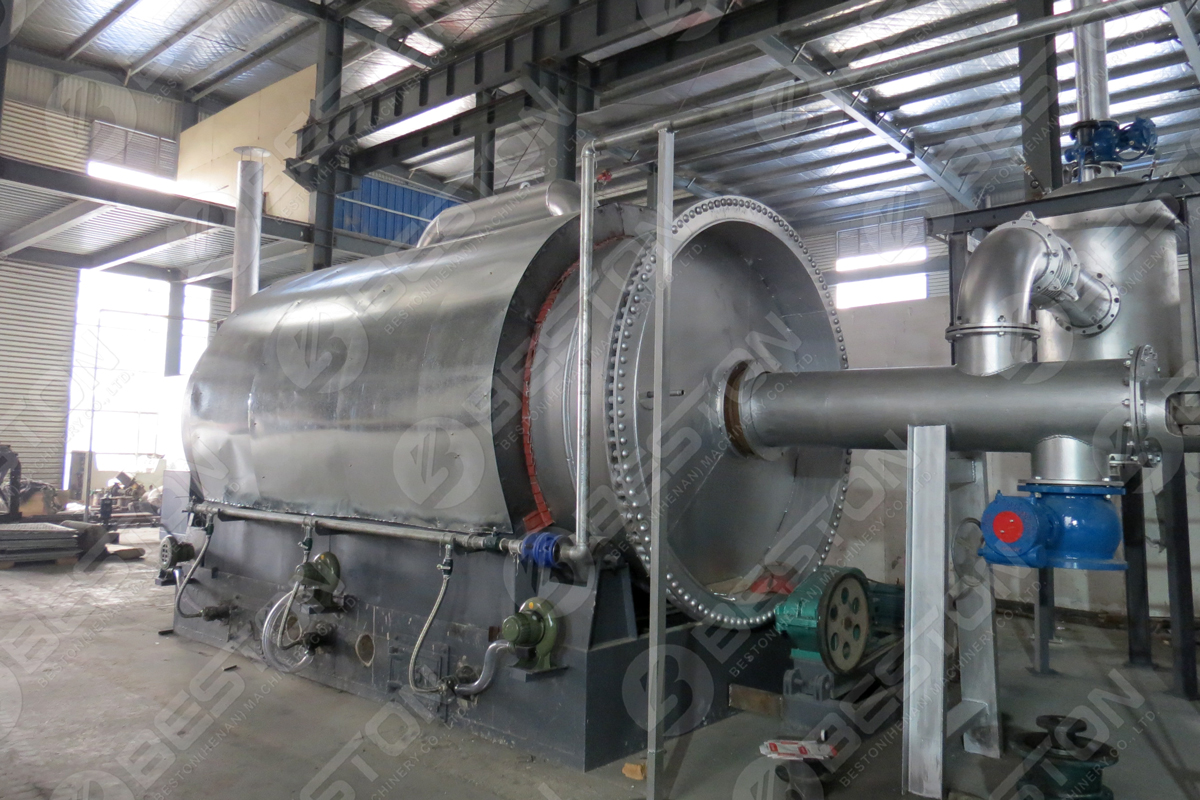

Pyrolysis is a process that converts waste materials into usable products, such as fuel, through the application of heat and pressure. Small pyrolysis machines are a type of waste management equipment that can be used to process small volumes of waste materials, making them an attractive option for businesses and individuals looking to reduce their environmental impact.

Here are some of the key benefits of using a small pyrolysis unit for waste management:

Increased Flexibility and Scalability

One of the main advantages of a small pyrolysis machine is its flexibility and scalability. These machines are designed to process small volumes of waste materials, making them suitable for businesses with fluctuating waste streams or those looking to test the viability of pyrolysis as a waste management solution.

Small waste pyrolysis plant is also easier to install and operate than larger systems, making them a more flexible option for businesses looking to add pyrolysis to their waste management operations.

Lower Initial Investment and Operating Costs

Small pyrolysis machines are typically more affordable than larger systems, making them a more cost-effective option for businesses looking to invest in waste management equipment. They also have lower operating costs, as they require less energy and resources to run.

Small pyrolysis machines also have a smaller footprint, meaning they take up less space and require less infrastructure to install and operate. This can further reduce the overall cost of ownership.

Small Footprint and Environmental Impact

In addition to the cost benefits, small pyrolysis machines also have a smaller environmental impact than larger systems. They generate fewer emissions and use less energy, making them a more sustainable option for waste management.

Small pyrolysis machines also have a smaller footprint, meaning they take up less space and have a lesser impact on the environment. This is particularly important for businesses operating in areas with limited space or environmental regulations.

Higher Quality End Products

Small pyrolysis machines often produce higher quality end products than larger systems due to their ability to process smaller quantities of materials more precisely. This can be particularly beneficial for businesses that rely on the quality of their end products, such as those producing fuel or chemical products. By using a small pyrolysis machine, businesses can more accurately control the chemical composition of their end products, resulting in a higher quality product that meets specific industry standards or customer requirements. More: https://www.bestongroup.com/pyrolysis-reactor-for-sale/.

Improved Safety and Health Risks

Small pyrolysis machines are also generally safer to operate than larger systems. They have fewer moving parts and generate lower levels of heat and pressure, reducing the risk of accidents and injuries.

Additionally, small pyrolysis machines produce fewer harmful emissions and waste products, reducing the risk of negative health impacts on workers and the surrounding community.

Conclusion

Overall, small pyrolysis machines offer a range of benefits for businesses and individuals looking to manage their waste more efficiently and sustainably. They are more flexible, cost-effective, produce higher quality end products, and are more environmentally friendly compared to larger systems. This makes them an appealing option for waste management. Get more details on another choice of portable pyrolysis unit.