Pyrolysis offers a promising pathway for converting waste biomass into valuable resources like bio-oil, char, and syngas. However, safety and environmental concerns are paramount when designing a pyrolysis project. This article explores key considerations for prioritizing these aspects throughout the project lifecycle.

Safety First

- Feedstock Selection and Storage: Carefully evaluate feedstock for potential contaminants or hazards. Implement proper storage facilities to prevent fires, explosions, or dust inhalation risks.

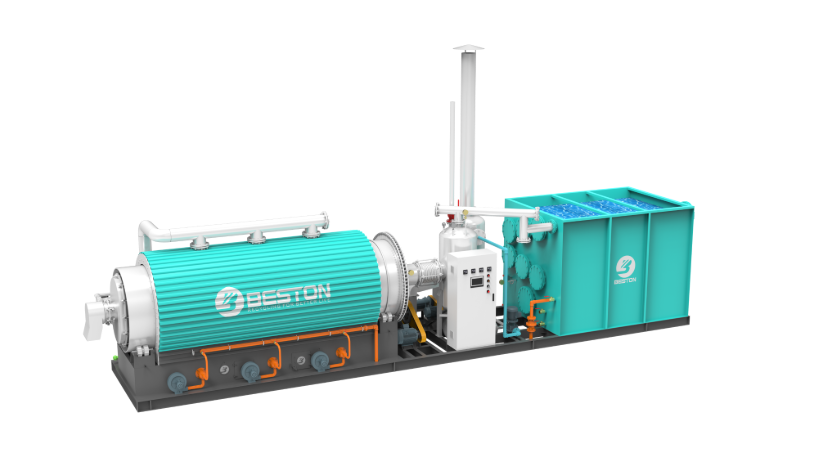

- Pyrolysis System Reactor Design and Construction: Prioritize robust reactor design with pressure relief valves, temperature control systems, and fire suppression measures. Utilize fire-resistant materials and adhere to relevant safety standards.

- Leak Detection and Prevention: Integrate leak detection systems for flammable gases and implement preventative measures like double seals and regular maintenance.

- Emergency Response Planning: Develop a comprehensive emergency response plan outlining procedures for fire, explosion, and personnel safety incidents. Train staff on safe operation procedures and emergency protocols.

Environmental Protection

- Feedstock Pre-treatment: Implement pre-treatment processes to minimize contaminants and maximize product quality, reducing the environmental impact of downstream processing.

- Emissions Control Systems: Employ effective gas cleaning systems to capture and treat harmful emissions like volatile organic compounds (VOCs) and particulate matter. Consider technologies like scrubbers, condensers, and biofilters.

- Wastewater Management: Design a closed-loop wastewater treatment system within the tyre/plastic to oil machine to minimize water usage and prevent contamination from process water. Options include biological treatment and reverse osmosis.

- Char and Bio-oil Utilization: Develop a plan for the sustainable utilization of char and bio-oil products. Explore options like co-firing in power plants or converting them into valuable bio-products.

Additional Considerations

- Life Cycle Assessment (LCA): Conduct a comprehensive LCA to assess the project’s environmental footprint throughout its lifecycle, from feedstock acquisition to product disposal. This helps identify areas for improvement.

- Community Engagement: Maintain open communication with local communities regarding project operations and potential environmental impacts. Implement measures to address concerns and minimize environmental disturbances.

Conclusion

By prioritizing safety and environmental protection from the outset, pyrolysis plant can contribute to a more sustainable future. The design considerations outlined above serve as a roadmap for developing responsible and environmentally conscious pyrolysis facilities. It’s crucial to evaluate and improve these practices as technology advances continuously.