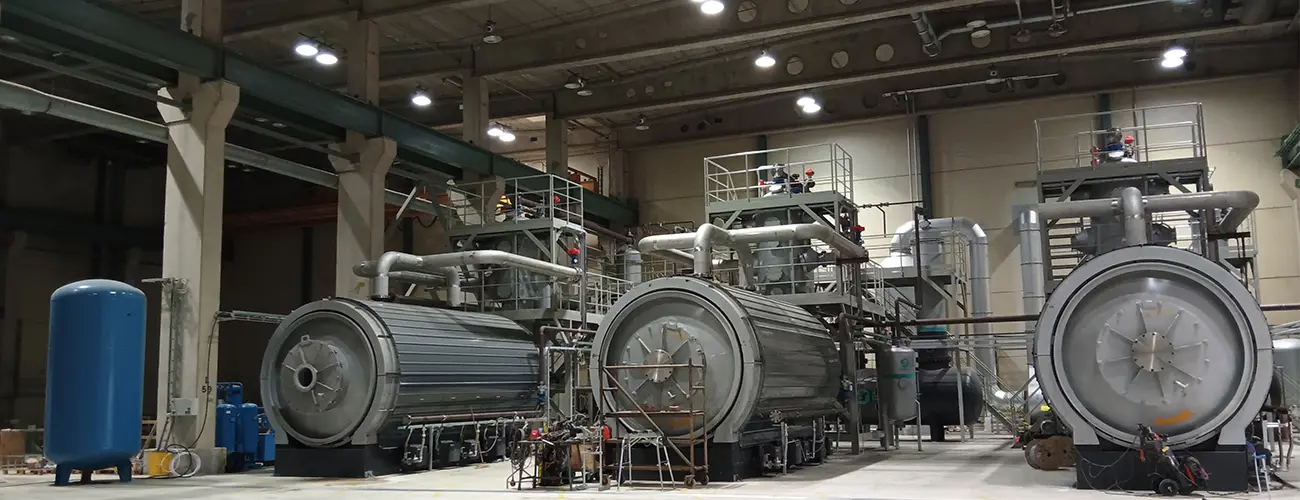

The plastic pyrolysis reactor is the core unit of a pyrolysis plant. Its design affects not only how plastics are converted under high temperature and oxygen-deficient conditions, but also the plant’s product distribution, energy efficiency, operational stability, safety, environmental performance, and overall economic viability. A high-quality reactor design is key to moving a pyrolysis plant from laboratory or pilot scale to long-term commercial operation.

1. Central Role in the Pyrolysis Plant

A typical pyrolysis plant includes:

- Feedstock pretreatment

- Pyrolysis reaction system

- Condensation and separation units

- Off-gas treatment

- Energy recovery systems

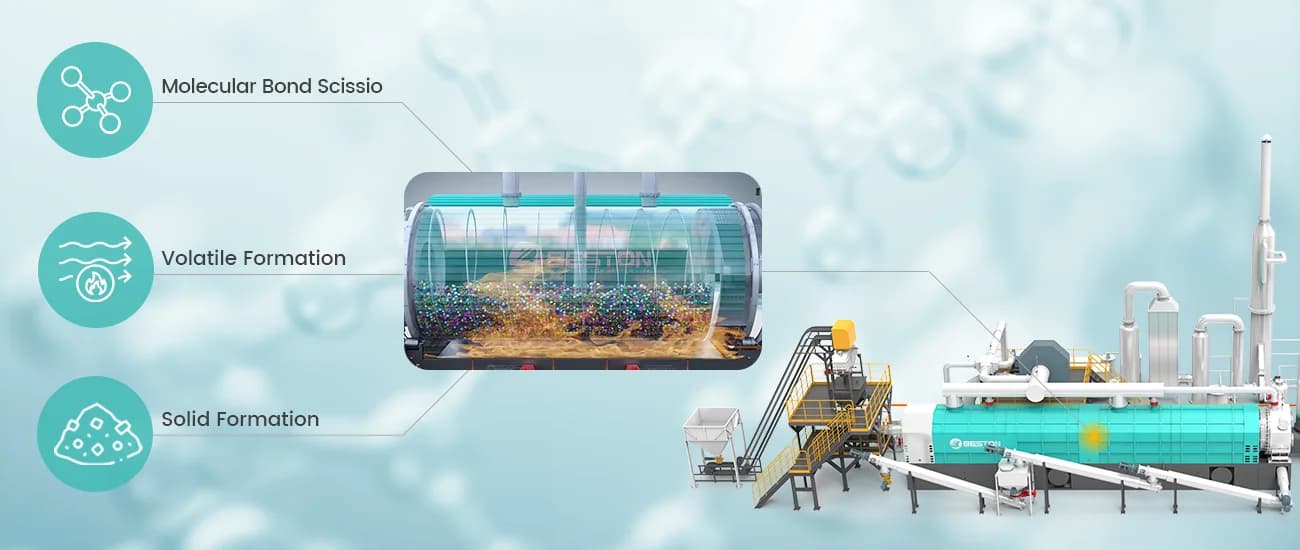

Among these, the reactor acts as the hub of material and energy flows. Inside the reactor, plastics break down into gases, liquids, and solids. Parameters like reaction temperature, residence time, heat transfer, and atmosphere control influence all downstream units. Poor reactor design can lead to incomplete pyrolysis, excess waxes or char, higher maintenance costs, and reduced liquid fuel yields.

2. Influence on Product Distribution

Reactor type (fixed-bed, screw, fluidized-bed, rotary kiln) directly impacts product composition. A well-designed plastic pyrolysis reactor allows precise control over heating rate and residence time, increasing selectivity for desired products such as pyrolysis oil or combustible gas. Product distribution, in turn, affects downstream systems:

- More gas → advanced gas purification or power generation

- More oil → larger condensation, storage, and upgrading units

Thus, reactor design fundamentally shapes the overall process flow.

3. Impact on Energy Efficiency

Energy efficiency is vital for economic and environmental viability. Reactor heating methods (indirect, electric, or hot gas) determine energy consumption. Efficient designs:

- Maximize heat utilization

- Minimize heat losses

- Integrate with energy recovery systems

For example, high-calorific gases produced can be reused to heat the reactor, reducing external energy needs.

4. Operational Stability and Maintenance

Industrial pyrolysis plants require continuous, stable operation. Reactor design affects reliability:

- Mechanical structure, sealing, and material handling prevent blockages and shutdowns

- Modular, easy-to-clean designs with online monitoring reduce maintenance and increase uptime

Thus, reactor design combines chemical reaction engineering with equipment and operational management.

5. Safety Considerations

Pyrolysis involves high temperatures, flammable gases, and complex materials. Safety requires:

- Proper pressure control

- Temperature regulation

- Safety devices (pressure relief, inert gas protection, emergency cooling)

A well-designed reactor of plastic into fuel machine ensures the safety of the entire plant.

6. Environmental Performance

Reactor design affects emissions and resource utilization:

- Efficient reactors reduce unreacted plastics and char

- Optimized reactions minimize harmful by-products, simplifying off-gas treatment

- Strong environmental performance improves regulatory compliance and public acceptance

This is crucial for sustainable plastic recycling and carbon emission reduction.

7. Conclusion

The plastic pyrolysis reactor has system-wide impacts on a pyrolysis plant:

- Determines reaction efficiency and product distribution

- Influences energy usage, stability, safety, and environmental outcomes

- Requires integration with plant-wide systems for commercial success

Optimizing reactor design in the context of the overall plant ensures high efficiency, reliability, and sustainable resource recovery. Pyrolysis Solution Expert – Beston Group Co., Ltd.