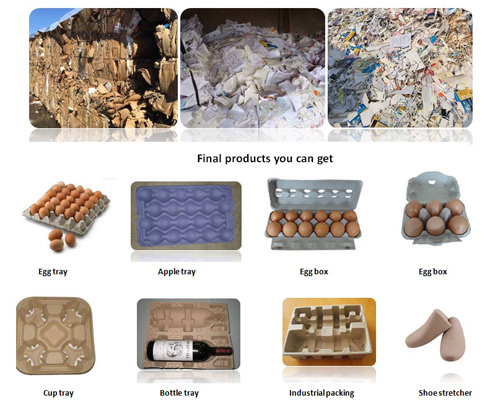

The right egg tray machine price (maquina moldeadora de pasta de papel)is out there on a product you can benefit from. But, you can’t just buy a machine of this kind without knowing what you’re in for. Since there are plenty of options, it helps to know how to shop for what will work well in your situation.

There are a lot of machines out there that you can buy from different sellers but some are not going to work well enough to be worth it. To get an idea of what you should be spending money on, you need to find out what reviews have been saying about different egg tray machines. That way, you can track down what has a solid reputation and avoid anything that doesn’t. You don’t want to spend money on what you know people don’t like because that is how you start wasting what you spend on this sort of thing.

A good machine(maquina para hacer bandejas de huevos) is going to cost a price that’s worth it. Before you spend anything on an egg tray machine, it’s very imperative to see what you can get it for from a few different people that are selling it. Don’t just buy one when you first find it because you need to be sure that you’re spending a fair amount instead of paying a higher rate than something should actually go for. Also, make sure you factor in what things like shipping will cost because that will influence what you have to pay to get what you’re interested in.

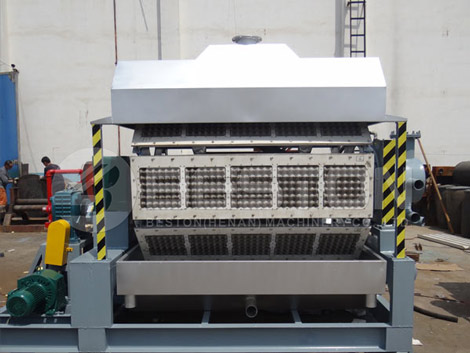

If you’re going to buy a used egg tray machine then it’s important that you ask the seller what kind of condition it’s in at this point in time. There is no need for you to spend your money on something that is barely in working order because that is how you end up wasting money on this kind of thing. You don’t want to buy something only to find out that it doesn’t work well and won’t withstand a lot of usage. If anything, make sure that they share photos of what they have with you so if their machine looks rough, you can avoid buying it(Bestongroup).

Can you send it back if you’re not happy with it for any reason? Or, can you only send it back if you find out that part of it is broken when you try to use it? Don’t think that you should buy from a company that says no returns, even if it’s cheaper because that’s how you get stuck with something that just doesn’t work. A good seller is going to admit when they make a mistake and then help you get out of the situation through their return policy.

Don’t pay an egg tray machine price(https://www.bestoneco.com/maquina-para-hacer-cartones-de-huevo/) that is not worth it because you didn’t do any research. Just use what you got information on here to proceed. That way, you get something that you know is going to work out for you and be worth the money you spend on it.