As the global focus shifts toward carbon neutrality and climate change mitigation, industries involved in carbon capture and storage (CCS) technologies are gaining prominence. Among these technologies, biochar production has emerged as a crucial method for sequestering carbon in a stable, long-term form. However, for biochar producers to capitalize on the growing demand for sustainable and verifiable carbon removal, obtaining certification from Carbon Dioxide Removal (CDR) platforms is becoming increasingly essential. This certification not only boosts the credibility of biochar production but also opens doors to new market opportunities, regulatory compliance, and increased profitability.

Elevating Trust with CDR Certification

The importance of CDR platform certification for biochar making machine lies in the added layer of transparency it offers. With growing awareness about climate change, there is increasing scrutiny of businesses claiming to provide eco-friendly solutions. Certification from a recognized CDR platform helps verify the effectiveness of a biochar machine in removing carbon from the atmosphere. It assures stakeholders, including regulators, investors, and consumers, that the process meets high environmental standards and delivers a tangible impact on carbon reduction.

CDR certification provides a formal acknowledgment of the biochar machine’s ability to sequester carbon over extended periods. This not only enhances the credibility of the business but also makes the biochar produced eligible for carbon credits, which can be traded in international carbon markets. By obtaining CDR certification, operators can leverage their production of biochar as a valuable asset in the global effort to combat climate change.

Compliance with International Standards

In the context of environmental sustainability, biochar production is not only an economic venture but also a regulatory concern. Governments around the world are implementing increasingly stringent carbon emissions regulations, and companies are required to meet these standards in order to operate legally. Certification from a CDR platform ensures that biochar machines comply with international standards for carbon removal.

Such certification processes involve rigorous verification procedures, ensuring that the pyrolysis machine for biochar adheres to best practices in carbon sequestration. These standards might include monitoring and reporting protocols, sustainability criteria, and methodologies for assessing the permanence of carbon storage. By obtaining CDR certification, companies demonstrate their commitment to meeting these evolving regulatory requirements, thus reducing the risk of legal or financial penalties related to non-compliance.

Access to Carbon Credit Markets

One of the most significant advantages of obtaining CDR certification is the opportunity to participate in carbon credit trading. Biochar, as a stable form of carbon sequestration, is increasingly recognized as a valuable tool in global carbon markets. When a biochar reactor for sale meets the certification standards, the carbon sequestered in the biochar can be registered as a verified carbon credit. This creates a direct revenue stream for biochar producers by allowing them to sell these credits to companies or organizations seeking to offset their own carbon emissions.

The price of carbon credits can fluctuate depending on market demand, but with the right certification, biochar producers gain access to a lucrative and expanding market. CDR certification not only facilitates the trading of these credits but also strengthens the market value of biochar as an environmental product. As more businesses, governments, and institutions adopt net-zero goals, demand for certified carbon credits will only grow, creating a potentially profitable long-term opportunity for biochar producers.

Improving Marketability and Consumer Appeal

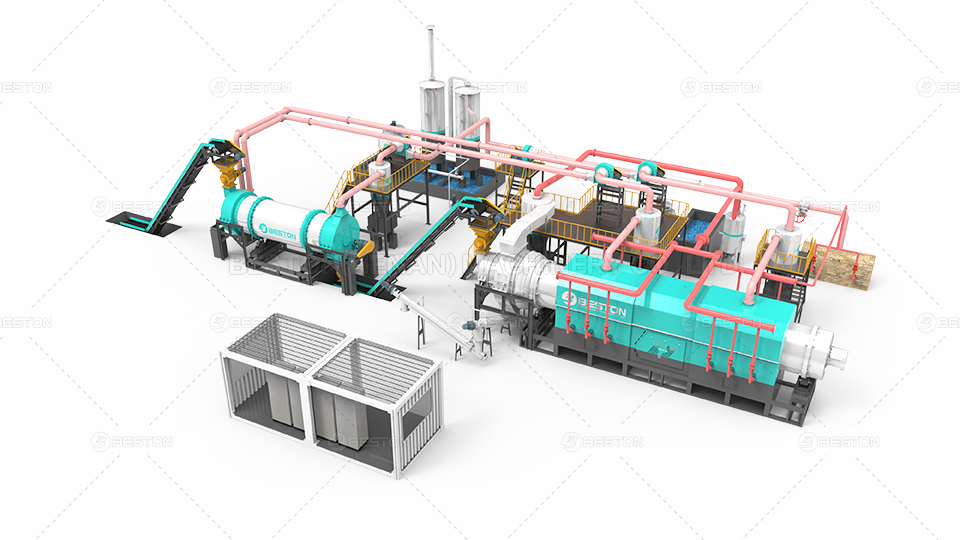

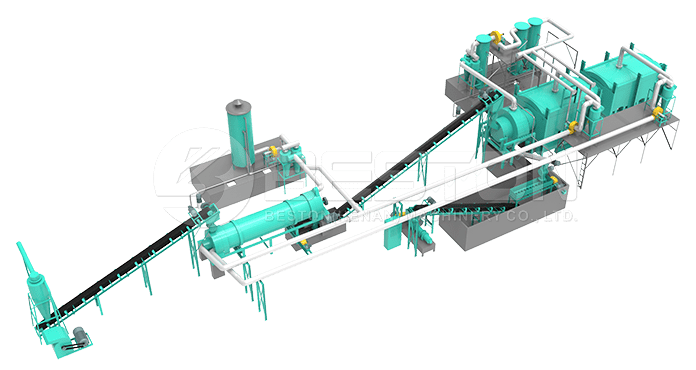

In today’s competitive market, businesses must differentiate themselves by demonstrating a genuine commitment to sustainability. Consumers and investors are increasingly favoring products that offer verified environmental benefits. Having a CDR-certified biochar machine provides an edge by communicating to the market that the biochar is not only produced sustainably but also verifiably contributes to carbon reduction efforts. For the most advanced biochar production solutions, please visit: https://www.bestongroup.com/

Certification from CDR platforms gives biochar producers a strong selling point. It allows companies to market their biochar as a product that has undergone stringent environmental assessments and meets recognized international carbon removal standards. This added credibility can lead to increased demand and higher prices, particularly in markets where consumers are willing to pay a premium for products with verified sustainability credentials.