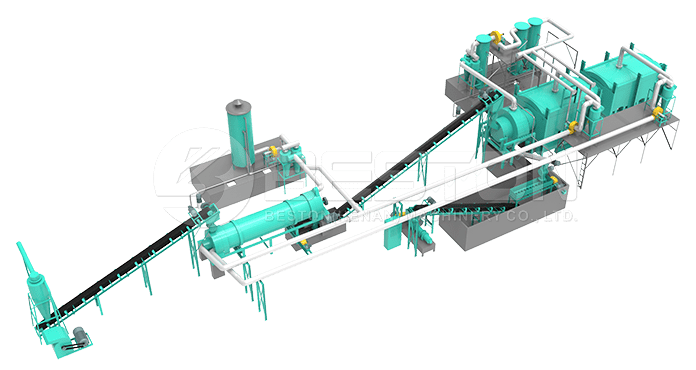

Bamboo charcoal making machine works to produce charcoal specifically from bamboo. There are other sources where charcoal can come from like coconut shells or wood, but the type from bamboo has a higher value in terms of efficiency and pricing. The charcoal machine works in a way that promotes environmental sustainability. Beston charcoal machine utilizes a one-fire-two-step method, which saves energy while also protecting the environment. The device consists of several parts that help make the process possible.

Bamboo Charcoal Machine Parts And Uses

Cooling System

Since the machine requires very high temperatures to operate, the cooling system is essential for the reduction of the heat on the bamboo charcoal to almost 30 degrees. Discharging the end product while in high temperatures can pose a risk; therefore, cooling is necessary to avoid accidents.

Biochar Production Equipment

Biochar production equipment is the main part of the charcoal production line. It adopts advanced carbonization technology to make charcoal from different raw materials. And the hourly capacity ranges from 500 to 3000 kg. More models can be found: https://mswrecyclingplant.com/biochar-production-equipment/.

Condenser System

The other two end products in the charcoal making process are vinegar and tar, which are produced by liquidating the combustible gas from the carbonizing process. The whole process takes place at the condenser system, then after collecting and storing for further usage.

Dedusting System

This system is used to remove the harmful elements in the tail gas. The procedure also aids in reducing the pollution effect since sulfur can cause damages if exposed to the air freely.

Charcoal Production Process

The first step is collecting bamboo, which is the primary raw material, and thoroughly shredding them to form far much smaller pieces. Transfer the product to the constant weight feeder through the conveyor. The feeder then delivers the bamboo to the upper layer of the machine to allow for drying and the flashing of steam. The process helps a great deal to reduce the water content to a level that is necessary for production. After some time, the bamboo gets fully dry, then it falls off and lands on the lower layer of the machine. From here, the next phase is carbonization. The procedure involves the use of high temperatures to allow for a variety of actions to take place efficiently. The results will include carbon collection, biomass pyrolysis, smoke discharge, and removal of sulfur. After achieving all these results, the carbonization process comes to an end, and you end up with your final product, pure bamboo charcoal. Check the charcoal making machine videos: https://www.youtube.com/channel/UC9zzn9329OyvomwOlrxNjSQ.

You can use the bamboo charcoal straight from production without requiring it to go through any other procedure. However, it is possible to make the charcoal into different designs like briquette and granular, but this entirely depends on the customer’s preferences and needs. During production, there is a generation of some combustible gas at the carbonization process. It goes through a recycling phase whereby it passes the dust collector and undergoes spraying. The procedure is vital since it leads to the production of tar and bamboo vinegar. The two products are essential as they can fuel up the charcoal making furnace from the outer part.

Your choice of the bamboo charcoal making machine will entirely depend on your preference and needs. It is advantageous and also versatile since it can use other materials like palm kernel shells and rice husks for production.