Recycling is one of the biggest issues of this century. As natural resources become scarce, governments try to reduce waste by collecting garbage and by turning it into useful items. This article reveals a few things to consider when seeking to invest in a garbage separation machine to help people in your local community recycle their waste and contribute to the protection of our planet.

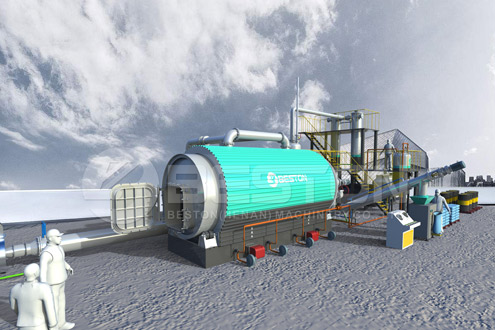

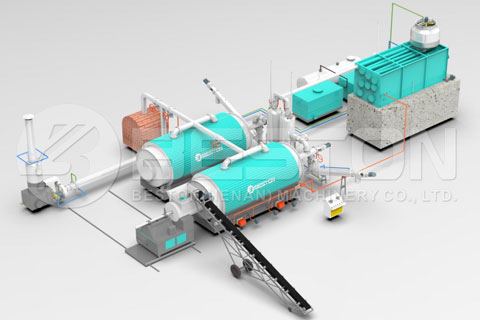

The first thing to decide upon is whether to separate the garbage and ship it to other recycling plants, or to invest in a full waste recycling line. Your decision will depend on your business plan, on your available space, and on your financial resources. If you don’t want to bother with setting up a huge recycling plant, you’d better stick to the idea of buying the best garbage separation machine you can find and let others do the rest of the job.

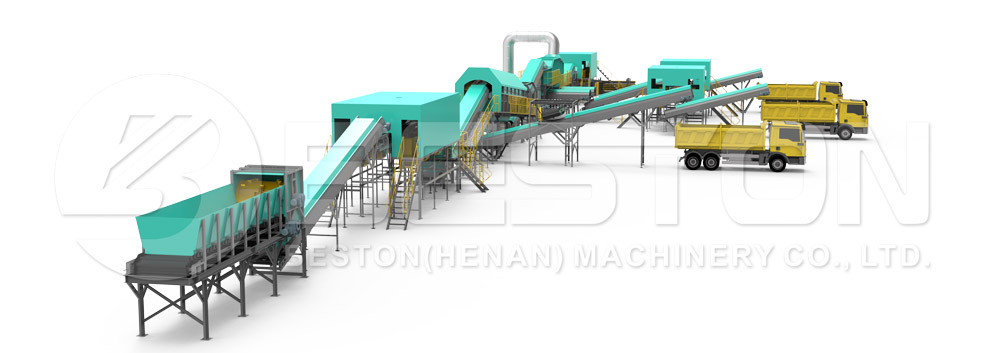

If you choose to buy only the garbage separation machine, you’ll have to choose the right configuration. This means that you have to consider including all main devices that will help you separate all four main categories of waste. These categories are: metals, plastic, organic matter and constructions materials. Each of them requires a specific device, so keep this in mind when you choose the configuration and the functions of your garbage separation equipment. Click here to know more: https://bestonpyrolysisplant.com/.

Remember that most garbage comes in plastic bags. In order to sort it, you’ll have to remove the bags. Fortunately, there are automatic machines that can do a great job at extracting those bags. Human workers aren’t that fast and that accurate, so don’t even think about hiring people to take all that garbage out of the bags.

Also, make sure you choose the right conveyor systems for the materials they will need to transport. Metal items or bulky materials might damage regular rubber belts. This means that you’ll have to choose metallic conveyor belts for these parts of your system. Furthermore, you won’t be able to transport and store sharp items with irregular shapes. The good news is that you have a handy solution, which is to invest in a compacting machine to mold separated waste into more manageable shapes. Besides, by compacting this garbage you’ll also save a lot of space.

In terms of keeping the costs to a minimum, the best you can do is to get several quotes from different manufacturers. Compare them side by side to pick the best one and remember to avoid compromising on quality only for the sake of a lower price. More information here: https://www.reddit.com/user/bestongroup/.