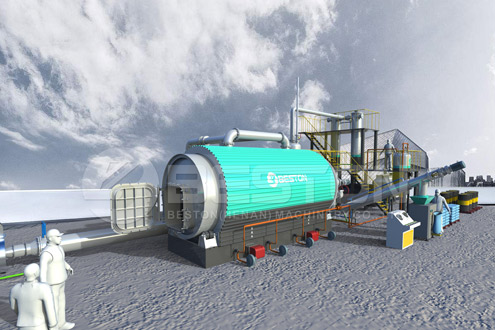

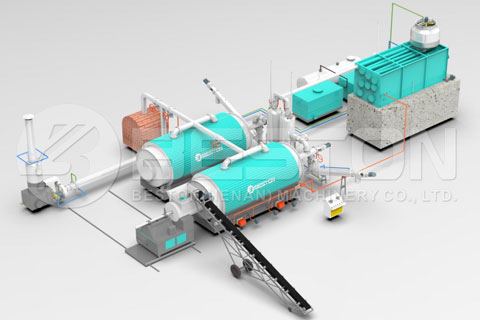

With the latest pyrolysis technology, it is possible to convert waste rubber into profitable commodities by waste rubber recycling machines. The proper disposal of waste that takes a long time to decompose, such as rubber, plastics, and car tires, is essential for protecting the environment. Furthermore, with the right recycling processes, it’s possible to extract a lot of money from those resource dense waste products. Tires, for example, contain carbon black, steel wire and fuel oil. With the right equipment, it is possible to extract all of those valuable materials from scrap tires and turn a rubber waste processing facility into a profitable eco-friendly plant. Make a research about rubber recycling machine price.

The pyrolysis process is basically just thermal decomposition. Waste materials are heated to high temperature in chamber free from oxygen. Since there is no oxygen, the raw materials vapourize rather than burn. Oil of varying viscosities can be liquified from the vapor using water-cooled condensers. There are many benefits to waste rubber pyrolysis plants including no combustion, no dioxin production, energy-efficient and environmentally friendly.

When old tires or waste rubber is incinerated, toxic gasses are produced with can cause environmental damage. It is for that reason pyrolysis processes are a much better alternative to burning when it comes to the disposable of rubber-based waste materials. Many tire scraping firms are desperate to get their hands on the newest continuous pyrolysis plant for sale, as they know it will allow them to generate large profits and earn them green points from government environmental protection schemes.

There are tire recycling plants in operation in multiple worldwide locations, including Brazil, Norway, Netherlands, Argentina, South Korea, China. Indonesia, Phillippines, Romania and South Africa. The largest tire graveyard is located in Sulabiya, Kuwait. The site is a potential gold mine for anyone with a waste rubber pyrolysis reactor. Fire outbreaks in landfill sites with lots of tires are common, as tires can trap methane gases.

Besides processing waste tires in a pyrolysis plant, there are many other ways in which tires can be recycled. They are commonly used in children’s adventure playgrounds, artificial sports pitches, carpet underlay, soundproof walls and more. Tires can also be used as effective flood defenses. Depending on their condition, it’s often possible to re-mold used tires to make them roadworthy. A large proportion of waste tires are burnt for fuel. The heat index value of typical tires exceeds that of common fossil fuels like coal.