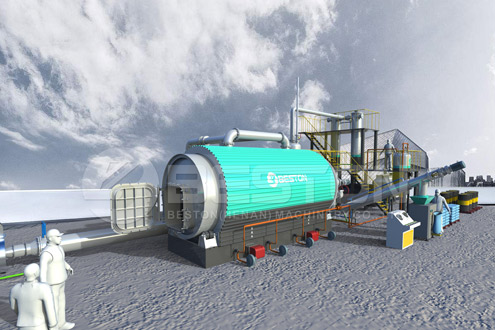

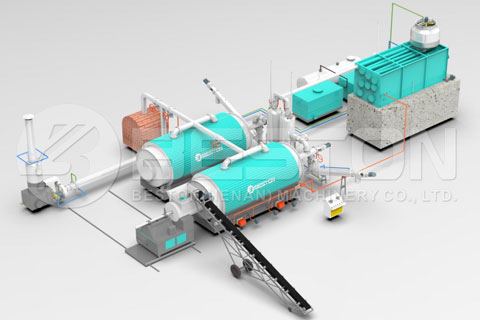

The small tire recycling plant allows you to make tons of oil quickly and in smaller spaces. Even though this machine is small, it can produce a ton of oil quickly so you end up getting the results you are looking for. This plant is a great investment in your business and it helps you produce all of the oil you need with no problems. The plant is very affordable and it is the type of machine that will work hard for you so you can get a lot of work done. The small tyre recycling plant is a great investment in any business.

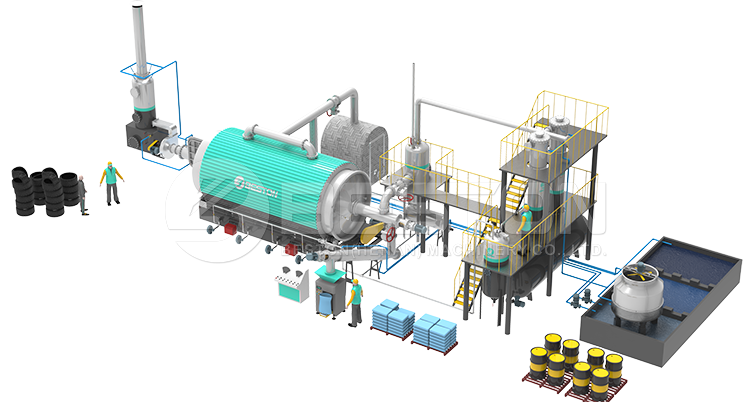

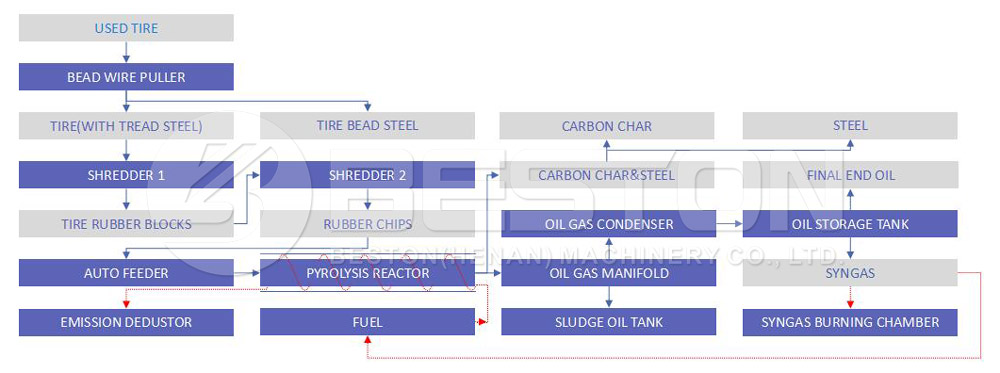

This plant has a lot of features that make it very easy to use. The plant takes waste tires and converts them into oil by heating them to a very high temperature in a technique called pyrolysis. You can make all of the oil you want with the machine and the oil is top quality as well. The oil is easy to sell and it can be used to run machines, heat things, and can even be refined and turned into gasoline.

The small tire recycling plant is designed to use the latest technology to process the tires. The machine is designed to run efficiently and it also recycles energy so you don’t spend as much money using it it and heating it. The plant stays cool because the reactor has two layers. This ensures that the plant is cool to the touch and that your worker has a comfortable working environment when they use this machine. They won’t get too hot or get burned when they are working with it. Know the cost estimate there https://tyrepyrolysisplants.net/tire-recycling-plant-cost.html.

The machine has a special auto-feeder that advances the tires into the reactor. The tires must be shredded before they go into the machine and they also have to be dry or else the process will not work properly.

When you are buying a small tire recycling plant you have to make sure that it is large enough for your needs. Though the machine is small it can still produce a lot of oil so you need to make sure that the machine will produce all of the oil that you need it to produce. There are some photos for you to view https://flipboard.com/@wastetocash/.

One of the best ways to ensure that you get the machine you want is to work with the supplier. The supplier will help you choose just what you need and they will assist you through the entire buying process and with the after-sales service as well. They will also install the machine for you and train your employees so they know how to use it. The supplier will also help you with after-sales service so you don’t have to worry about any problems with the machine in the future.