Does making money from waste tyres sound interesting to you? If so, you might want to consider starting a business in the tyre recycling pyrolysis plant industry. Unlike many other types of businesses, a tyre recycling plant can generate profits year-round, and it helps to save the environment at the same time. With the right machinery, you can turn waste tyres into markable fuel oil via the pyrolysis process.

Waste tyres can be very difficult to break down, and they can cause a lot of problems to the surroundings when they are disposed of irresponsibly. By investing in the best continuous pyrolysis plant and starting a waste tyre recycling business, you can not only make a lot of money, but you can also help to safeguard the natural environment. Waste tyres are a big problem in many cities around the world, so you should have no problem sourcing raw materials to keep your business in operation 24 hours a day. That’s also why there are more and more pyrolysis plant manufacturers in china now.

What Is A Tyre Pyrolysis Plant?

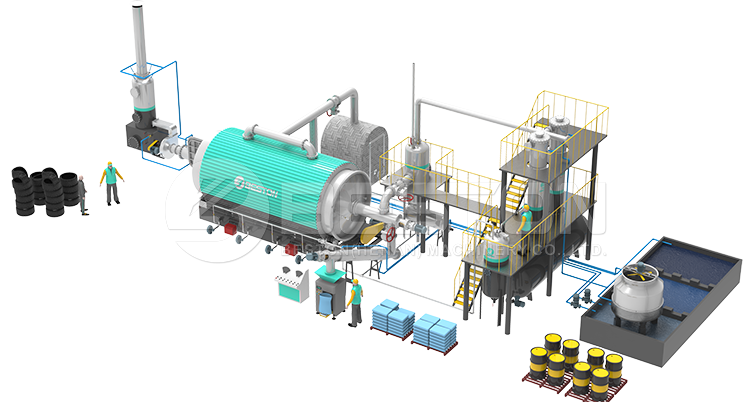

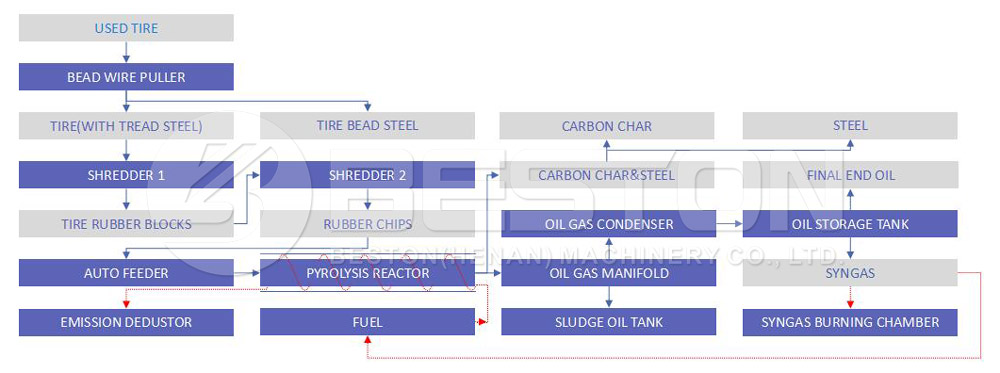

A tyre pyrolysis plant is a machine that turns old tyres into fuel oil, black carbon, and steel. There are two different types of pyrolysis reactors: rotary and horizontal. A plant with a rotary reactor can process 6 to 16 tons of tyres each day, while a horizontal reactor has a daily capacity of up to 24 tons. A plant with a rotary reactor is known as a semi-continuous pyrolysis plant, while a plant with a horizontal reactor is referred to as a continuous pyrolysis plant. The type of plant you choose to buy for your tyre recycling business will depend on both your budget and production rate requirements.

End Products From A Waste Tyre Pyrolysis Plant

During the process of pyrolysis, waste tyres are converted into useful products by high temperatures in an oxygen-absent environment. The end products have many uses and have high commercial value. The four main end products are outlined below:

Fuel Oil: The fuel oil that is produced by a tyre pyrolysis plant can be sold directly to industries like power plants, cement factories, and the food production sector. It can also be put through a distillation machine and refined into diesel and gasoline, which have high market values. You can find more useful information about the uses of fuel oil now.

Steel Wire: The steel wire produced has a high monetary value. It can be sold to steel factories where it will be turned into steel bars and steel and iron rods.

Carbon Black: When putting through a grinder, carbon black can be converted into high-quality black carbon powder, or activated carbon, which has a high value. With briquetting equipment, it is also possible to turn the carbon black into carbon blocks, which can be sold for enhanced profits.

Combustible Gases: Some of the combustible gases produced can be used as fuel to reheat the continuous pyrolysis plant reactor reducing a plant’s running costs. The gases can also be sold to other industries.

Hopefully, the information presented above has prompted you to think about investing in the waste tyre recycling industry and learn more about continuous pyrolysis plants.