Biomass is usually a material that simply goes to waste. Many companies try to find ways of affordably discarding this material so that they can save money. What they may not be aware of is the fact that this material can be used to produce marketable materials, combustible products like charcoal that can be sold very easily. To do this, you must first have a machine that can utilize the biomass in a way that will allow you to make it marketable. This is one may want to consider investing in an apparatus that can make pellets that comes in the form a biomass pellet machine for sale.

How Do Biomass Pellet Machines Work

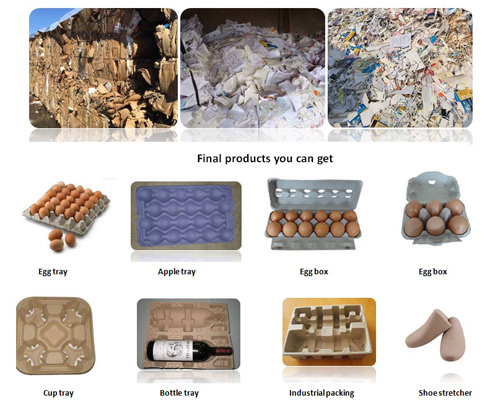

Biomass can be converted into charcoal and burnable fuel by going through a certain process. You can use material such as sawdust, rice husks, palm kernels, and many other combustible materials. However, sawdust is likely the easiest material to use. It is combined with other materials that will allow it to not only hold together, but can also help with the combustion process when they enter into the pellet machine that will burn the fuel. Forced through small openings, this will create the tiny pellets which will be quickly dried and solidified. These can then be packaged, sold to companies that are either just selling the pellets or they can also produce them for their own business. Get high quality wood pellets machine here.

How Do They Work?

First of all, you need a source for biomass. This can be bark, branches, straw, grass, or any form of wood such as sawdust. You are going to produce small pellets which can be inserted into these pellet burning machines, and the same machines can even make pellets for animals to consume. There is a small round apparatus which has multiple holes in different diameters. This is how you can control the sizes of the pellets that are made. Also referred to as a pellet mill, the motor is going to turn on, combined with a reducer shaft, and this will force the material through the openings until the pressing process is completed.

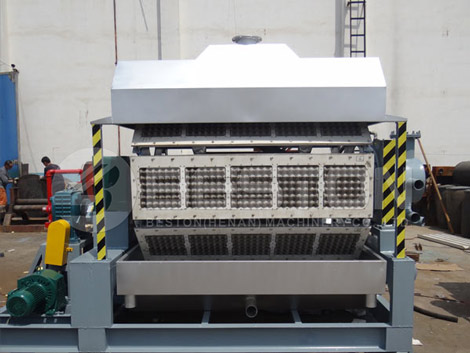

Different Components Of The Pellet Processing Machine

The pellets machine itself is the base of the unit. You are going to have a silo where the initial materials will be placed. There will be tubes, fans, types, and a feeding conveyor that is going to deliver the material into the silo’s of the process can begin. All of this is self-contained, especially on the units that are designed for the highest amount of output. You can find companies that make very good models, at reasonable prices, that can help you produce millions of these pellets every year.

Your research will likely lead you to several companies that will offer you the opportunity to obtain one of these unique machines. The world is continually looking for sources for good quality pellets, and you can produce them very easily if you have the material available. You also need to have a quality sawdust pellet machine that can do all of the work for you. Simply start looking today for top businesses that are in this industry that produce the best pellet machines that produce biomass.