Buying a tyre recycling machine can be the beginning of a lucrative business. You can make a nice living out of collecting waste and turning it into useful products. Rubber is one of the recyclable materials that are readily available in all urban areas. You can turn rubber into fuel by using a method known as pyrolysis. While you don’t need to be a chemist to turn waste tyre into oil, you do need the right equipment and a solid business plan.

The first thing to do before shopping for tire recycling machine for sale is to research all available types of such equipment with their specific advantages and drawbacks. You also need to know what volume of waste tyre you can expect to recycle per day, in order to know what size of machine to buy. The other thing you need to think about is whether you want to buy a new machine or a used one. As you can imagine, used ones are less expensive. If you’re on a shoestring budget, this can be a good solution to start your business with a smaller investment.

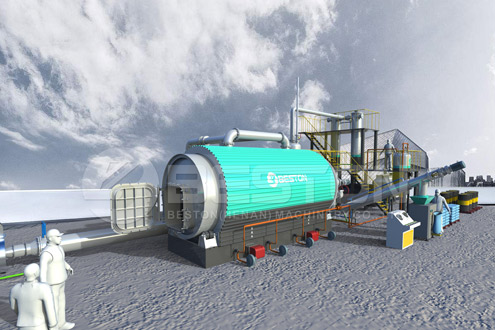

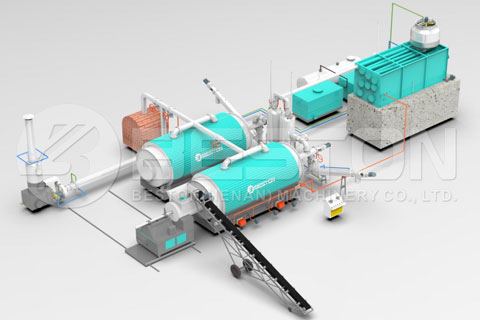

If you can afford it, you should seek to purchase an automatic, continuous pyrolysis machine. This would allow you to control the production process and to keep your costs at bay by limiting the number of employees. There are lots of such machines, with prices between $3,000 and $100,000 US. The final price depends on the processing capacity of the machine among other things.

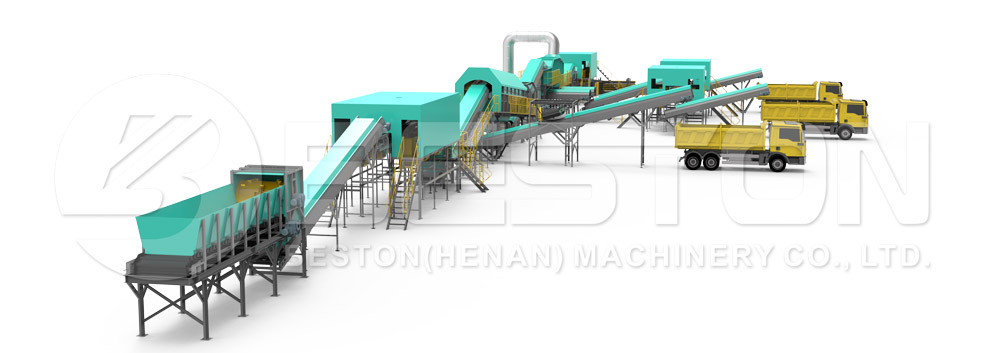

In terms of places where you can find such tyre pyrolysis plant, consider searching for manufacturers rather than resellers, such as Beston Machinery. You’ll find lots of recycling equipment and machinery manufacturers online, either by using your favorite search engine or by narrowing down the listings of business and trade directories such as AliBaba, Amazon Marketplace, and eBay.

No matter how tempted you may be to buy your tyre recycling machine from the first pyrolysis machine manufacturer you com across, resist this urge and ask a few of these companies for a quote. Make sure you offer them enough details to help them prepare accurate cost estimates and installation timings. After you get all estimates, compare them closely to see which one would best suit your business. Beware that the price is usually less important than other factors such as the warranty, the insurance, and the shipping conditions.

If you want to be on the safe side in regard to the payments, consider using an Escrow service. All sellers will be happy to agree with this suggestion. More relevant information about the tyre to oil plant here.