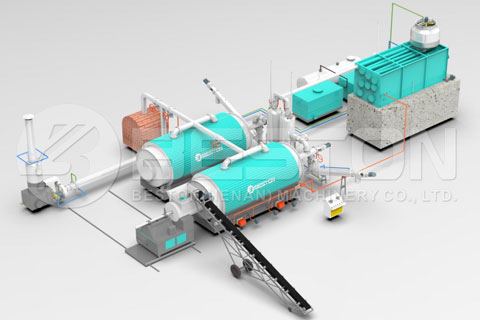

When you need to turn tires into oil, you need to invest in a pyrolysis plant. This plant takes any type of rubber and turns it into oil. The pyrolysis equipment heats the rubber up to a very high temperature where it breaks down and turns into oil. The oil is high quality and it can also be refined into gasoline.

The oil that the pyrolysis plant makes is high quality and it is perfect for heating buildings or cooking. The rubber materials that you need to put in the machine are affordable and you can often even get them for free.

You are doing something great for the environment when you choose this plant because it doesn’t emit pollution and is also equipped with plenty of anti-pollution devices. No pollution is going to escape this machine when you use it because the anti-pollution protection is so good. If you wanna get a competitive pyrolysis equipment cost, contact Beston.

The machine is good for the environment and it helps you take old tires out of the landfills so they can be used for other things. The machine produces high-quality oil which is going to have a high resale value and you can sell it for a great price.

It is important to protect the environment whenever possible and this machine ensures that you can do this with ease. The machine allows you to create oil fast as well. The process is fast and efficient which means you get to produce lots of oil for a very affordable price. This machine has the power you need to make money fast.

When you need to find a pyrolysis plant for sale make sure that you use a service that will export the machines to anywhere in the world. The right manufacturer will ensure that you get your machine exactly where you need it so you don’t experience any issues. Read this pyrolysis plant business plan.

You need to make sure that your plant can be shipped anywhere before you place your order. This makes it easier to take care of your oil needs. The plant is built to last and it is made with very high quality materials. The best steel and electronic parts are used to ensure that the machine operates at high performance with no issues. You don’t want to have issues with your phone and when you choose the right plant you won’t have to worry about this.

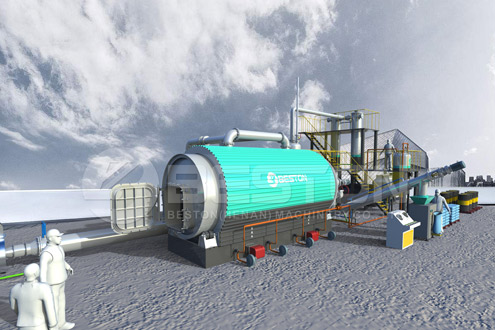

A good pyrolysis plant is a great addition to any manufacturing business since it will work so hard to make oil. The machine has an auto feeder that feeds the materials directly into the machine. It also discharges the oil on the other side of the machine which is efficient and convenient.

The reactor is built to last so when you choose a pyrolysis plant for sale make sure that that reactor you choose is stable and easy to use. The right plant will fit your price range and will have all of the features you are looking for. If you need to produce oil, you need a pyrolysis plant. Find the reliable pyrolysis machine manufacturers.