A paper tray making machine has a seemingly simple design. It takes in raw material in the form of pulp and turns it into a dry paper product as per the mold fitted into the machine. However, there must be something that differentiates high quality machines from all the others in the business. In this article, we will discover what really differentiates high quality paper tray making machines from all the others.

There are quite a few things which separate high quality machines from all the others in the market. One of the things is the number of molds that can be used in the machine. Another thing is the efficiency of the machine. The third most important thing is the level of automation. We will now discuss all these factors in detail.

Number of Molds

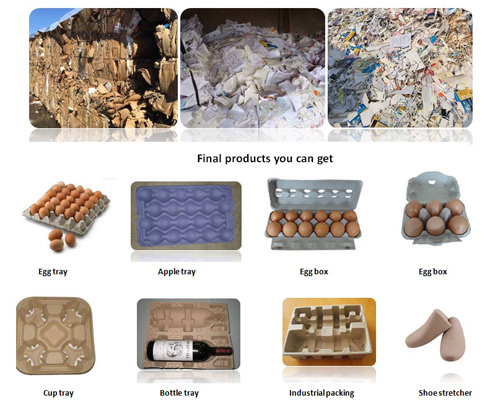

A machine that converts pulp into paper products can be used for making a wide range of products including egg trays, fruit trays, shoe supports, different kinds of packaging material for use in different industries and a whole range of other products. The only thing that matters is the design of the mold. High quality machines are able to use a huge range of molds allowing the producer to make different kinds of products that are in demand in a variety of industries. In short, a high quality machine offers a lot of flexibility and various kind of products can be made in a single machine. Also, it’s easy to change molds. More cost information can be found: https://bestongroup.ru/oborudovaniye-dlya-proizvodstva-yaichnykh-lotkov/

Efficiency

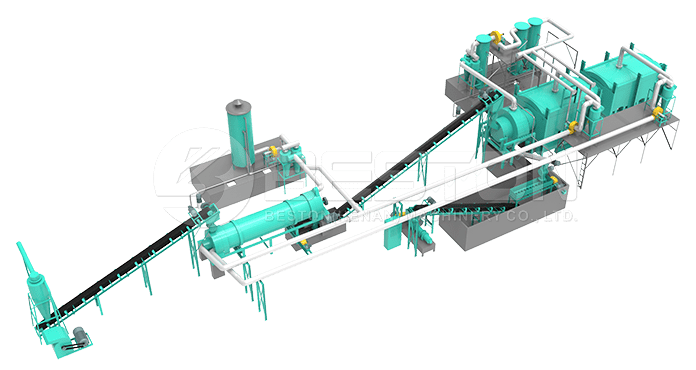

Efficiency refers to the power consumption of the machine along with its rate of production and inclusion of all the components in the system to make a complete product. Keep in mind that a paper tray making machine is not sufficient in itself to create an end product that can be sold in the market. A whole system needs to be there including a pulp making machine, the tray making machine and the drying system in order to prepare good quality products with consistent quality. Many reputed companies supply the whole system as one package for efficient operations. Contact the China Beston Machinery to know more info and stat your business!

Level of Automation

The level of automation has a huge impact on the consistency in quality of the end products. Needless to say, it also helps you save money on labor costs and makes sure that you can run your factory 24 x 7, if there is huge demand for the products. While a fully automated machine is obviously going to be expensive as compared to a semiautomatic or a manually operated machine but it is going to be much more profitable in the long run. You will continue to save money on labor costs and you will also have an edge over your competitors by consistently delivering high quality products. Needless to say, you can also keep your factory running 24 x 7 due to high level of automation.

Conclusion

Overall, investing in a machine for making paper trays (инвестиции в машину для изготовления лотков для бумаги) and related products can be a highly profitable business opportunity provided you prepare a well thought out business plan. Don’t forget to use the above mentioned tips to choose the right machine for your business in order to have a leg up on the competition.